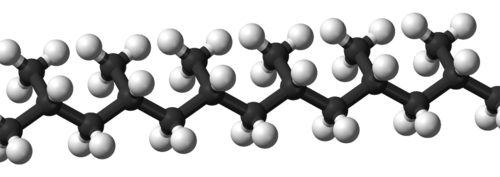

PP Structure

The physical properties of semi-crystalline polymers such as polypropylene are dependent on several key factors.

- Chemical Composition

- Molecular Weight and Distribution

- Chain Structure (Tacticity)

- Morphology

Chemical Composition

The chemical composition of a polymer refers to the basic make up of the polymer. The two most common examples of this might be PE and PP where the chemical makeup differs between with the base monomer of each polymer. IE ethylene and propylene respectively.

Molecular weight

The molecular weight is determined by the length of the polymer chains. The chain length of polymers determines both the molecular weight as well as the key physical properties of the polymer. When the chain lengths of a polymer have very uniform lengths it is said to have low polydispersity. The number of repeat units in the chain determines the degree of polymerization (DP) as well as the molecular weight. Many important properties of the final result are determined primarily from the distribution of lengths and the degree of polymerization. The degree of polymerization has a dramatic effect on the mechanical properties of a polymer. As chain length increases, mechanical properties such as ductility, tensile strength, and hardness rise sharply and eventually level off.

This is controlled through the polymerization process. Two of the most common processes are the Zigler Natta process and the Metallocene process. In general, the ZN process produces polymers with unbranched chains of higher molecular weight than the metallocene process. The ability to accurately control polymer chain length in the Metallocene process makes it the preferred method when a more narrow range of physical properties are desired in a polymer.

Molecular weight is important because it influences mechanical properties such as stiffness, strength, viscoelasticity, toughness, and viscosity. Unlike small molecules, however, the molecular weight of a polymer is not one unique value. Rather, a given polymer will have a distribution of molecular weights. The distribution will depend on the way the polymer is produced. For polymers we should not speak of a molecular weight, but rather of the distribution of molecular weight.

The MFR (Melt Flow Rate) or MFI is an indication of PP's molecular weight.

The level of molecular weight most directly affects the molding process, especially in working with the problem of the shrinkage rate of a mold, but also processing conditions during production cycle. In addition, molecular weight also influences the same basic material's natural characteristics. High molecular weight with low MFR makes for difficult molding, and the nature of the material's rigidity is slightly reduced, yet its impact strength is enhanced.

Molecular weight distribution

Molecular weight distribution (MWD), or polydispersity, is defined as the ratio of the weight-average to the number-average molecular weight. In plastics, resin having MWD values ranging between 3 to 5 are considered narrow MWD, 6 to 12 as medium, and 13+ as broad. The MWD of a resin influences processing efficiency and quality, especially in two-way stretched film and high speed fiber production. Catalysts such as Metallocene are used to give resin a narrower MWD, allowing for better processing characteristics.

MWD conditions can be seen in Figure 3.2.

MWD primarily affects those properties related to flow, and resin manufactures use the PI value (Polydispersity Index) to identify resins. At the same average molecular weight, resins with broad distributions (higher PI value) have better flow, (and thus are softer) during processing than those with narrow distributions. Better flow also indicates greater impact strength and transparency when cooled.

|

Density |

Molecular Weight |

Molecular Weight Distribution |

|||

|

Increase |

Decrease |

Increase |

Decrease |

Increase |

Decrease |

|

|

Environmental Stress |

▼ |

▲ |

▲ |

▼ |

▲ |

▼ |

|

Impact Strength |

▼ |

▲ |

▲ |

▼ |

▼ |

▲ |

|

Stiffness |

▲ |

▼ |

▼ |

▲ |

▲ |

▼ |

|

Hardness |

▲ |

▼ |

▼ |

▲ |

▲ |

▼ |

|

Tensile Strength |

▲ |

▼ |

▲ |

▼ |

▲ |

▼ |

|

Warpage |

▲ |

▼ |

▼ |

▲ |

▲ |

▼ |

|

Abrasion Resistance |

▲ |

▼ |

▲ |

▼ |

▲ |

▼ |

|

Flow Processability |

----- |

----- |

▼ |

▲ |

▲ |

▼ |

|

Melt Strength |

----- |

----- |

▲ |

▼ |

▲ |

▼ |

|

Melt Viscosity |

----- |

----- |

▲ |

▼ |

▼ |

▲ |

|

Copolymer Content |

▼ |

▲ |

----- |

----- |

----- |

----- |

|

Permeation |

▼ |

▲ |

----- |

----- |

----- |

----- |

Chain Structure

Polymers can be made with different tacticities, or stereo-specificities. There are three basic chain structures: isotactic, syndiotactic, and atactic. Of these three, isotactic has the highest crystallinity because the chains can pack closely together. Atactic polymers are noncrystalline because of the wide spacing of the polymer chains. A structure's tacticity refers to the way its pendant groups, (small chains of atoms attached to the longer backbone chain of atoms) are arranged alongside the backbone chain of a polymer. In an atactic structure there are methyl groups on both sides of the chain, but they follow no particular order. With this kind of structure, the polymer doesn't crystallize. If methyl groups are placed in one position relative to the carbon chain, such as in syndiotactic and isotactic structures, the polymer does crystallize, thus stiffening the chains. Until catalysts were developed, only soft, atactic PP could be made. However, with the use of catalysts, PP can be made isotactic, or more rigid. Most PP used commercially today is isotactic.

等規立構 Isotactic

間規立構 Syndiotactic

等規立構 Isotactic

間規立構 Syndiotactic

無規立構 Atactic

Morphology

While there are a few polymers that are totally amorphous, the morphology of most polymers is semi-crystalline. That is, they form mixtures of small crystals and amorphous material and melt over a range of temperature instead of at a single melting point. The crystalline material shows a high degree of order formed by folding and stacking of the polymer chains. The amorphous or glass-like structure shows no long range order, and the chains are tangled. Influencing the polymer morphology is the size and shape of the monomers' substituent groups. If the monomers are large and irregular, it is difficult for the polymer chains to arrange themselves in an ordered manner, resulting in a more amorphous solid. Likewise, smaller monomers, and monomers that have a very regular structure (e.g. rod-like) will form more crystalline polymers.

Header Image Credit: PakpongICCH444 Usage: CC BY-SA 4.0